SUMISEAL

CatalogNo.987[Watertight crimp connector tube]

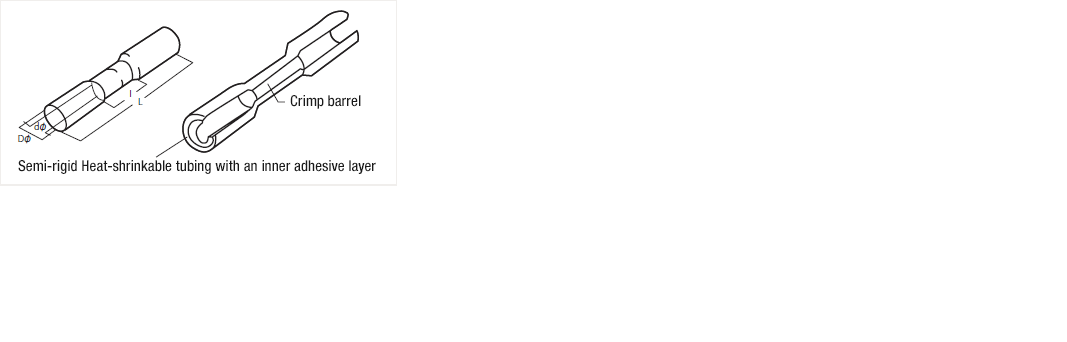

■ Sumiseal comprises a copper crimp barrel and heat-shrinkable semirigid two-layer polyolefin tube. The crimp barrel connects electrical wires when crimped, while the tube insulates the wires. Hot-melt adhesive is coated over the inner wall of the two-layer tube so that the adhesive melts and fills the gap between the crimped barrel and wire when the tube is shrunk. Because of the above feature, Sumiseal can be used to connect electrical wires, and at the same time, protect the wire joint from water, dust, and other undesirable external influences. Moreover, connecting wires using this product makes the wire joint smoother, more compact, and more reliable than conventional tape-based waterproofing processes.

Applications

- ■ Protection of wire harnesses in automobiles and wire joints in household electrical appliances, ships, machine tools, and other equipment from water, oil, vibration, and dust

Basic Properties

| Category | Heat shrink tubing |

|---|---|

| Material | Electron beam cross-linked semi-rigid polyolefin, hot-melt adhesive, and copper crimp barrel |

| Flammability | Non Flame Retarded |

| Shrink temperature | min. 120℃ |

| Continuous operating temperature | -40 to 105℃ |

| Specifications/Approvals | SFP standard (R4-0200) |

| Marking on Surface | ― |

| Available colors | Red, Yellow, Blue |

| Flexibility | Semi-rigid |

| Environmental Compliance | RoHS,ELV |

| Industry | Automotive,Construction machinery,Industrial machinery,Electronics |